Study and optimization of process parameters for deformation machining stretching mode

Downloads

Published

DOI:

https://doi.org/10.58414/SCIENTIFICTEMPER.2024.15.2.31Keywords:

Deformation machining, Surface roughness, Hardness, Grey Relation Analysis, Analysis of Variance (ANOVA)Dimensions Badge

Issue

Section

License

Copyright (c) 2024 The Scientific Temper

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

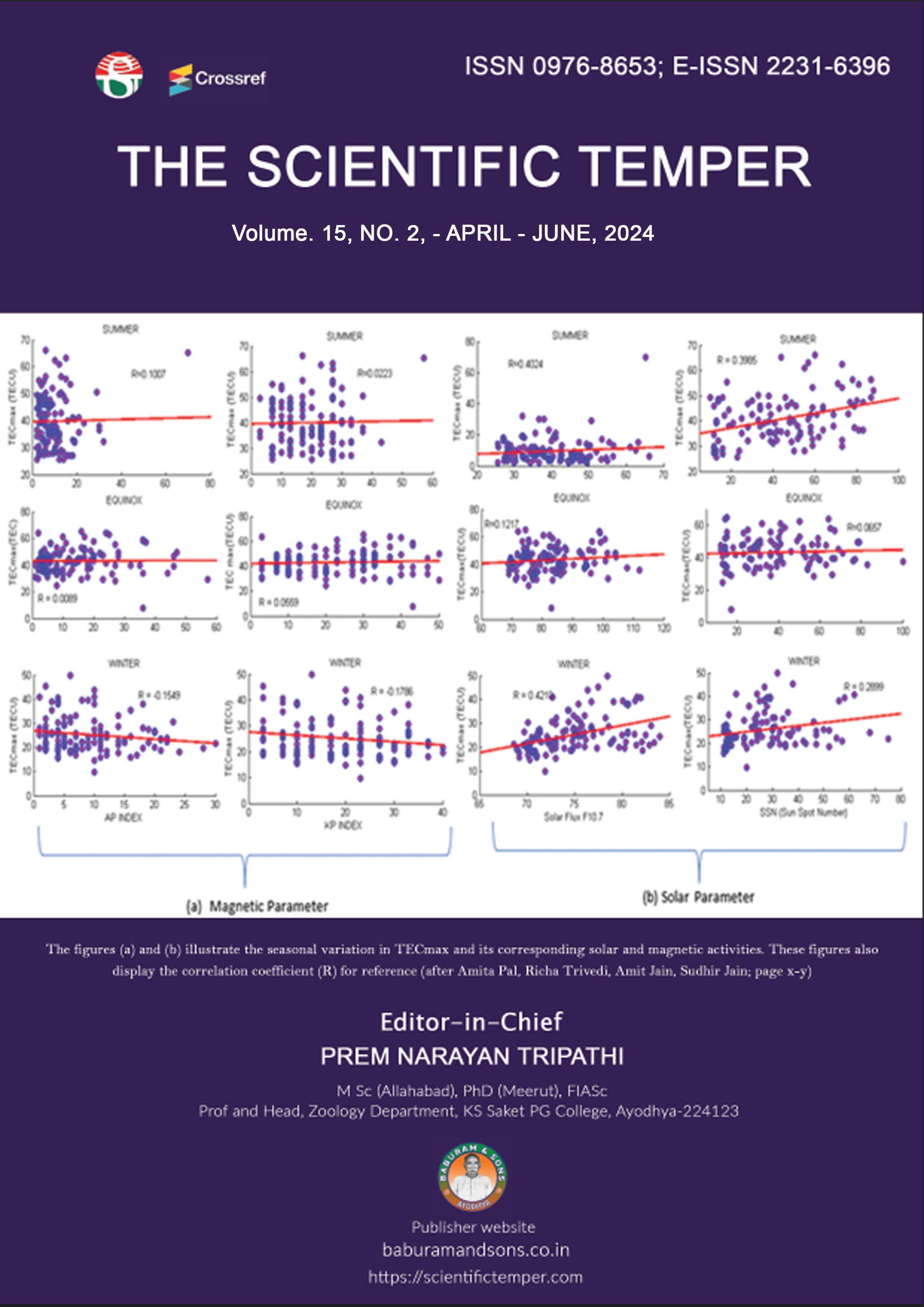

Monolithic thin-structure parts with intricate geometric designs are employed in a variety of aeronautical, medical, marine, and automotive applications, which include the moldlines of the fuselage, turbine blades, impellers, avionic shelves, irregular fins, prostheses, bone and joint support, and skull plates. The deformation machining process is the solution to this challenging and difficult-to-manufacture high-quality components with intricate narrow geometries at competitive prices. The aim of the present study is to assess the effect of process parameters of the deformation machining process wherein a thin, floor-like structure is created by milling and is then formed using a single-point incremental forming tool. Investigation involves the design and development of tooling required for the process followed by feasibility checking of the process. To examine the impact of different process parameters on the process response, the experiments were carried out using the design of experiments. The findings of this study indicate that different process parameters, including spindle speed, tool diameter, incremental step depth, and feed rate, have a substantial impact on the process response, like thickness, surface finish, and hardness. Uneven and non-uniform surface patterns during SEM indicate that it is needed to examine the impact of process parameters. This research involves the feasibility study of a new hybrid technique of deformation machining. Conventionally, a metallic structure is produced by joining various components through welding or by fastening. These methods require additional expenditure on equipment, storage, floor space, human resources, etc., with higher lead time. Joining increases weight and reduces fatigue strength. The creation of monolithic structures can eliminate all these disadvantages.Abstract

How to Cite

Downloads

Similar Articles

- Sowmiya M, Banu Rekha B, Malar E, Assessment of transfer learning models for grading of diabetic retinopathy , The Scientific Temper: Vol. 14 No. 02 (2023): The Scientific Temper

- Narmetova Y. Karimovna, Abdusamatov Khasanboy, Abdinazarova Iltifotkhon, Nurbaeva Khabiba, Mirzayeva Adiba, Psychoemotional characteristics in psychosomatic diseases , The Scientific Temper: Vol. 14 No. 04 (2023): The Scientific Temper

- Shivali Kundan, Neha Verma, Zahid Nabi, Dinesh Kumar, Satellite radiance assimilation using the 3D-var technique for the heavy rainfall over the Indian region , The Scientific Temper: Vol. 13 No. 02 (2022): The Scientific Temper

- Nisha Rathore, Purnendu B. Acharjee, K. Thivyabrabha, Umadevi P, Anup Ingle, Davinder kumar, Researching brain-computer interfaces for enhancing communication and control in neurological disorders , The Scientific Temper: Vol. 14 No. 04 (2023): The Scientific Temper

- Jayaganesh Jagannathan, Dr. Agrawal Rajesh K, Dr. Neelam Labhade-Kumar, Ravi Rastogi, Manu Vasudevan Unni, K. K. Baseer, Developing interpretable models and techniques for explainable AI in decision-making , The Scientific Temper: Vol. 14 No. 04 (2023): The Scientific Temper

- Pravin P. Adivarekar1, Amarnath Prabhakaran A, Sukhwinder Sharma, Divya P, Muniyandy Elangovan, Ravi Rastogi, Automated machine learning and neural architecture optimization , The Scientific Temper: Vol. 14 No. 04 (2023): The Scientific Temper

- Purnendu B. Acharjee, Bhupaesh Ghai, Muniyandy Elangovan, S. Bhuvaneshwari, Ravi Rastogi, P. Rajkumar, Exploring AI-driven approaches to drug discovery and development , The Scientific Temper: Vol. 14 No. 04 (2023): The Scientific Temper

- Lakshmi Priya, Anil Vasoya, C. Boopathi, Muthukumar Marappan, Evaluating dynamics, security, and performance metrics for smart manufacturing , The Scientific Temper: Vol. 14 No. 04 (2023): The Scientific Temper

- Nilesh M. Patil, P M. Krishna, G. Deena, C Harini, R.K. Gnanamurthy, Romala V. Srinivas, Exploring real-time patient monitoring and data analytics with IoT-based smart healthcare monitoring , The Scientific Temper: Vol. 14 No. 04 (2023): The Scientific Temper

- Naveena Somasundaram, Vigneshkumar M, Sanjay R. Pawar, M. Amutha, Balu S, Priya V, AI-driven material design for tissue engineering a comprehensive approach integrating generative adversarial networks and high-throughput experimentation , The Scientific Temper: Vol. 15 No. 01 (2024): The Scientific Temper

<< < 16 17 18 19 20 21 22 23 24 25 > >>

You may also start an advanced similarity search for this article.